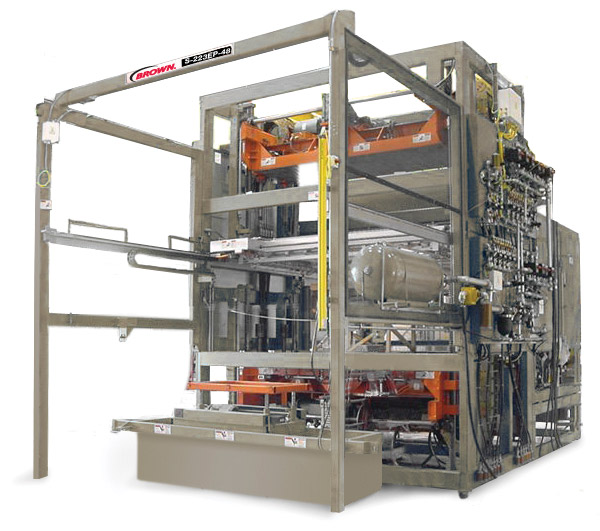

BROWN® SP-SERIES PRESSURE SHUTTLE THERMOFORMERS

HIGH PRODUCT DEFINITION - QUCK CHANGEOVERS

Shuttle systems are an excellent choice for forming large products with heavy-gauge materials, ideal for shorter runs and frequent changeovers. The Brown SP-Series adds pressure to the shuttle vacuum process giving you the ability to achieve greater product detail. In addition to the variety of standard vacuum forming processing techniques, the Brown SP is equipped with the strongest platen structures in the industry. The superior deflection rating makes it possible to run high-tonnage applications such as twin-sheet forming and in-mold trimming. The machines utilize the latest open architecture programming, non-proprietary hardware and incorporate the highest quality readily available components. The Brown SP-Series is built stronger to last longer, giving you a competitive edge in your industry.

Equipment specification

Feature:

3D FEA Designed Platens

Direct Drive Platens

Closed Loop Multi-Axis Motion Control

Machine Designed for future upgrades

Mold Sizes – from 3′ x 4′ to 12′ x 24’+

Platen Speed – 10″ or 12″ per second

Platen Strokes – from 15″ to 100″+

Male and Female Bayonet Platen Locking System

Air-Bag and Guided Pressure Plate Seal System

High Output Part Cooling System

Ideal Oven Zoning – Ceramic Elements

Solid State Relays Oven Control

Oven Fire Protection – Air Jet

Point IR Sheet Temperature Monitoring

Aluminum Extrusion Clamp Frames

Sheet Load and Part Unload Lift Table Systems

Allen-Bradley PLC and PC Interface Machine Controls

HMI Touch Screen with Intuitive Screens

Infinite Product Recipe Storage and Recall

Air-Conditioned Main Electrical Panel(s)

Option:

High Tonnage Platen Strokes for Compression Molding and In-Mold Trimming

Third Motion Platen Feature for Additional Sheet to Mold Clamping

Motorized Bayonet Lock Adjustment System

Optional Oven Elements – Quartz, Panel or Halogen

Heater Control Modules (HCM) – Highest Diagnostics

Oven Fire Protection – Teflon Oven Curtain System

AL-90 Quick-Change Clamp Frames

Articulating and Multi-Zoned Clamp Frames

Full Sheet Temperature Scanning Systems

Interior Oven Lighting and Viewing Window(s)

Motorized Sheet Sag Tracking Oven Feature

Servo Regulated Valving with Part Recipe Recall

Custom Load/Unload Automation – Robotics

Vast Process Sensing and Trending Solutions

Quick-Change Tooling Systems

Latest Safety Scanners with Muting Functionality

Ancillary Integrated Equipment – MTC Units, Trimming, Granulating, etc.

UL, CE, CSA & HSE Approvals Available

International Voltages Available

Bi-Lingual Labels and HMI Screens Available