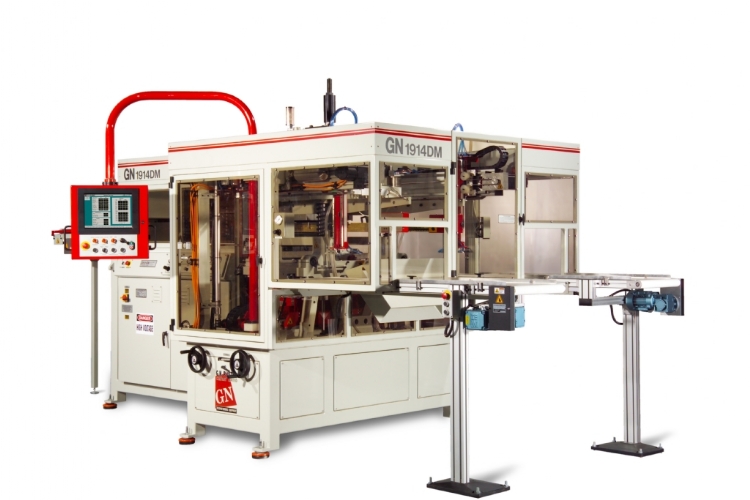

GN Thermoforming Equipment

LEADERS IN THERMOFORMING MACHINERY AND TOOLING GN Thermoforming Equipment was founded in 1981. GN's early goal was to provide innovative, superior quality machinery and tooling that would advance the global thermoforming industry, while offering a level of service that would well exceed customers' expectations. Today, the company is internationally recognized as one of the most trusted manufacturers of thermoforming machinery and tooling. Leading manufacturers of plastic packaging in more than 70 countries now rely on our quality products and unparalleled customer service. We are proud of introducing GN thermoformers in East Asia market. Should you have any inquiry please contact us sales@cmteastasia.com or ring the office.