Tooling

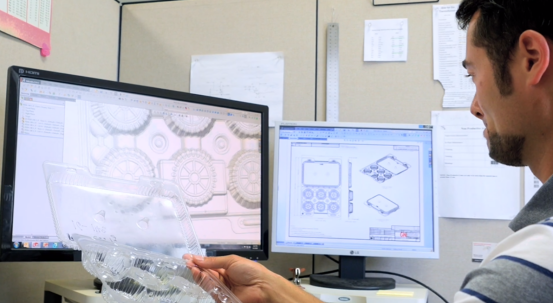

CUSTOM TOOLING WITH UNMATCHED PRECISION

We’re a global leader in custom tooling design and mould-making, giving our customers a proven advantage in the international marketplace. Our knowledge, expertise, and access to the latest technology guarantee our ability to design and produce top quality products at maximum conversion rates.

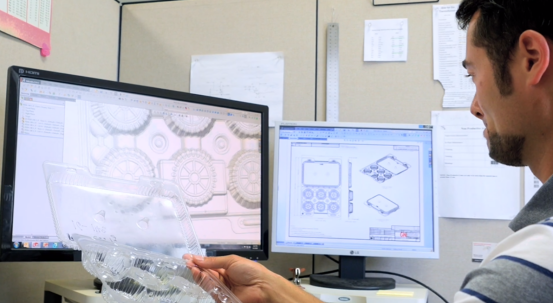

Efficient, high quality mould-making

In business, timing is critical. That’s why we take a streamlined approach to mould-making—taking your ideas through the concept, prototyping, and production-testing phases, in the shortest possible time.

Innovative tooling designs

As a pioneer of common edge tooling design for contact heat thermoformers, we know how important it is that your tooling is always top of the line. GN has adapted this cost-effective solution to be used on our newest plug assist machines. We love to work with our customers to develop innovative designs that increase efficiency and reduce waste.

Tooling Partners

GN collaborates with industry leading tool manufacturers. Many of these partners operate and test their tooling on GN thermoformers - this ensures quality, consistency, and a smooth transition on arrival at our customer’s facilities

A full-service approach

Our tooling design specialists will start the mould-making process by transforming your sketches or ideas into a part drawing or prototype sample for your approval. With every comprehensive proposal, we provide:

a tool layout

production data

cycle times

recommended materials

The tooling process ends with rigorous testing to confirm accuracy and reliability. We’ll also help prepare you for production at your own facility by providing detailed set-up instructions and technical support.

Please Contact Us to discuss your tooling projects.