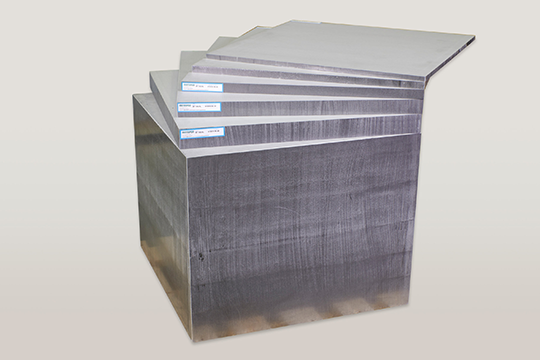

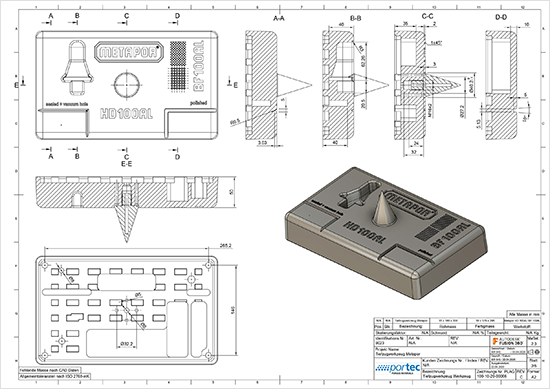

METAPOR

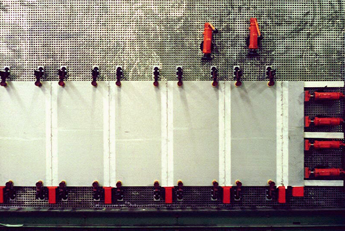

Portec is an independent Swiss Company. It is the inventor and producer of METAPOR® and ESPOR® micro-porous materials. Our name stands since 1991 for Swiss Quality, innovative solutions and reliable high-tech products. We are proud of introducing Metapor products in East Asia market. Should you have any inquiry please contact us sales@cmteastasia.com or ring the office.