TOOLVISION

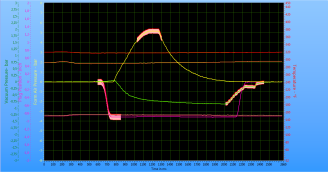

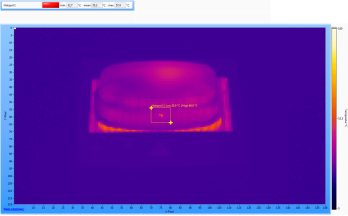

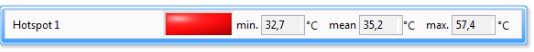

Based in Germany, TOOLVISION® - CLEVER MEASURING TECHNOLOGY SINCE 2004. High-end, real-time measuring technology. For optimal thermoforming and perfect end products. We are proud of being Tool Vision Asia Exclusive agency. For more product details, please talk to us sales@cmteastasia.com or ring our office.